Battery Packs Customized Copper Tube Liquid Cold Cooling Plate Heat Exchange

Why choose us Nanjing Metalli-your ideal partner for thermal management and metal fabrication solutions Since 2008, Nanj

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | 22nm1011 |

| Transport Package | Carton Box or Plywood Case with Films Protection |

| Specification | custimize |

| Trademark | OEM |

| Origin | China |

| Production Capacity | 50000PCS/Year |

Product Description

| PRODUCT SPECIFICATION FOR WATER COOLING PLATE | ||

| NO. | ITEM DESCRIPTION | CONTENT |

| 1 | Product Name | Water cooling plate;water cooling heat sink;aluminum cooled plate |

| 2 | Material | Aluminum,Aluminum+Cooper tube |

| 3 | Detailed Size | As per customers' design |

| 4 | Sample Service | Samples are availabe for prototypes within 1 week |

| 5 | Production Process | Aluminum Plate Cutting--Grooves Making--Embedding Tubes(Friction Stir Welding)--Epoxy adhesive filling--CNC Machining--Cleaning--Inspecting--Packing |

| 6 | Surface Treatment | Degreasing,(Black) Anodizing,Sand Blasting,Painting,Chromating and Laser marking |

| 7 | Reference Standard | GB/T 3190-2008,GB/T 14846-2008,ISO 2768 |

| 8 | Experience | More than 20 years professional manufacturing experience |

| 9 | Application | LED Lighting,Inverter,Welding Machine,Communication Device,Power Supply Equipment,Electronic Industry,ThermoelectricCoolers/Generator,IGBT/UPS Cooling Systems and so on high power device |

Nanjing Metalli-your ideal partner for thermal management and metal fabrication solutions

Since 2008, Nanjing Metalli has been focusing on thermal management field. Our capabilities cover a wide range that provide you one-stop solution quicker and easier. Our main capabilities include:

1. Vacuum Brazing and Controlled Atmosphere Brazing

2. CNC machining

3. Welding

4. Aluminum extrusion

5. Aluminum die casting

6. Sheet metal fabrication covering laser cutting, stamping, drawing and bending

7. Surface coating

We emphasis prototype process. we use our vast experience in fluid dynamics, thermal performance, and material compatibility to optimize your design. To perform advanced thermal analysis, our engineers use simulation software like CFD, 6 Sigma. In addition to providing expert thermal and mechanical design engineering, we ensure that your products fit DFM concept so that your products can be built to your exact specifications as well as meet your delivery schedule.

We see quality aspects from manufacturing viewpoints. Focusing more on monitoring and minimizing process variable to keep stable quality level. Delivered products are performed 100% inspection or testing. Less worries of quality risk and loss

Our lean manufacturing and continuous improvement program aim at eliminating all wastes that do not add values. Our customers do not need to pay for wastes. The cost will be more and more competitive that help grow up your business and build your success.

Related Products

-

![Professional Good Price Friction Stir Welding Fsw Liquid Cold Cooling Aluminum Plate CNC Milling Machining 6061 Flat Aluminum Cooling Plates for EV Car Battery]()

Professional Good Price Friction Stir Welding Fsw Liquid Cold Cooling Aluminum Plate CNC Milling Machining 6061 Flat Aluminum Cooling Plates for EV Car Battery

-

![Quick Lead Time Aluminum Bonded Fin Heat Sinks Heat Sink]()

Quick Lead Time Aluminum Bonded Fin Heat Sinks Heat Sink

-

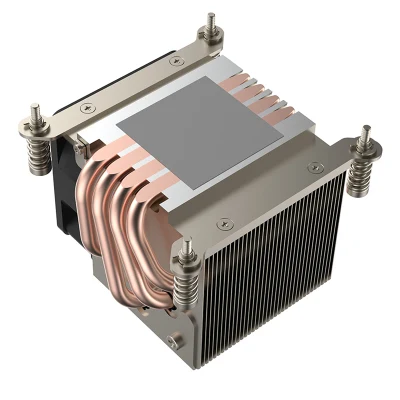

![Best Aluminum Fin Heat Pipe LGA1700 Active CPU Heat Sink for 2u Server]()

Best Aluminum Fin Heat Pipe LGA1700 Active CPU Heat Sink for 2u Server

-

![Customized Aluminum Tower Fin Stack Copper Plate Heat Sink with Heat Pipes]()

Customized Aluminum Tower Fin Stack Copper Plate Heat Sink with Heat Pipes