Customized Supper Thin Pure T2 Copper Vapor Chamber

Product name: Customized supper thin pure T2 copper vapor chamber Product Description Vapor Chamber. Vapor Chamber techn

Send your inquiryDESCRIPTION

Basic Info.

| Noise Level | Low |

| Application Fields | Electronics |

| Certification | ISO |

| Condition | New |

| Transport Package | Carton |

| Specification | 305*305*0.16mm |

| Trademark | NA |

| Origin | China |

| Production Capacity | 500000 |

Product Description

Product name: Customized supper thin pure T2 copper vapor chamber

Product Description

| Product Name | Vapor Chamber for electronic device |

| Material | T2 Copper |

| Function | Heat dissipation |

Vapor Chamber.

Vapor Chamber technology is similar to heat pipes in principle, but differs in the way it conducts heat. The heat pipe is a one-dimensional linear heat transfer, while the heat in the Vapor Chamber is transferred on a two-dimensional surface, making it more efficient.

Company Intriduction

Related Products

-

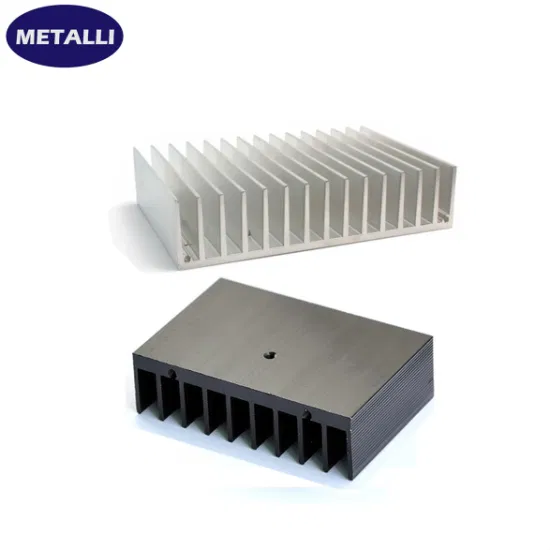

![Quick Lead Time Aluminum Bonded Fin Heat Sinks Heat Sink]()

Quick Lead Time Aluminum Bonded Fin Heat Sinks Heat Sink

-

![Customized High Thermal Conductive Copper Vapor Chamber for CPU Smart Phone]()

Customized High Thermal Conductive Copper Vapor Chamber for CPU Smart Phone

-

![Dongguan Custom CPU Heat Sink Manufacturer Heat Pipe Skived Heat Pipe Zipper Fin Copper Pipe Heatsink Parts]()

Dongguan Custom CPU Heat Sink Manufacturer Heat Pipe Skived Heat Pipe Zipper Fin Copper Pipe Heatsink Parts

-

![High Power LED Skived Fin Heat Sink Aluminum Skived Fin Heat Sink]()

High Power LED Skived Fin Heat Sink Aluminum Skived Fin Heat Sink